The Global Standard in AI-Driven Sensing & Analytics

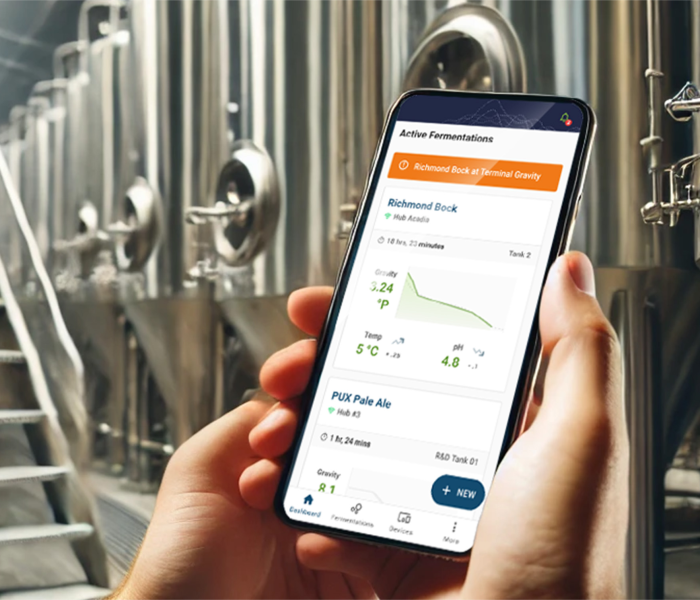

Sennos is the pioneer and leader in automated fermentation monitoring and analysis. We unify cutting-edge hardware, AI-powered analytics, and intuitive interfaces to deliver the industry’s most advanced sensing platform. Our in-tank sensor array and AI-driven cloud technology provide real-time insights and complete visibility into every aspect of your production, eliminating guesswork, ensuring consistency, and empowering you to optimize every decision as you confidently scale your operation.

Sennosystem for Fermentation

Explore the Sennosystem

Learn More

Powering the Future of Fermentation

From brewing to biofuels, Sennos transforms fermentation-based industries with real-time sensing, AI-driven analysis, and predictive insights—helping businesses scale smarter, reduce waste, and maximize efficiency.

The World's Largest Fermentation Database

Sennos is powered by the world’s deepest fermentation data engine, trained on tens of thousands of real fermentations to unlock predictive, high-resolution insight. Every data point makes the system smarter, helping producers refine quality, improve efficiency, and maximize profit—at scale, and in real time.

Hours Monitored

Fermentations Analyzed

Data Points Collected

When you start getting maxed on production, one or two days of additional tank time can be a lot. At the end of the year this adds up to an additional full turn in a tank.

— Denver SmythFounder/Head Brewer

Sennos increased our efficiency in terms of our pitch rate and that we’re able to create a better product long term.

— Ed Fabrycki Jr.Co-Founder

This is the best tool you can have for consistent fermentations.

— Chris BakerDirector of Brewing Operations

I was able to use temperature alerts to inform me of rising temperatures in 6 batches of beer due to solenoid failures, allowing me to proactively address the issues resulting in a savings of $30,000-$45,000 depending on batch size.

— Seth OrrHead Brewer